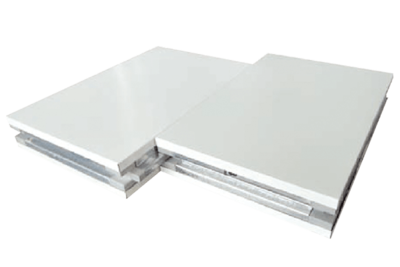

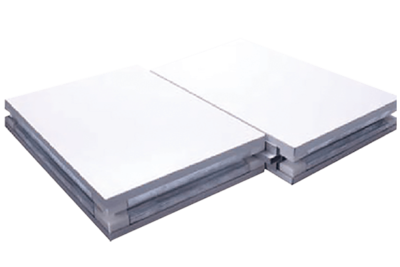

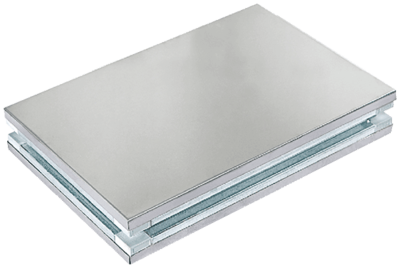

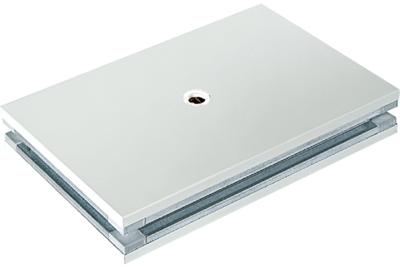

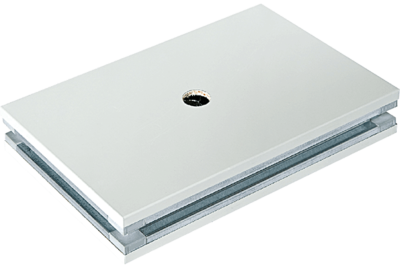

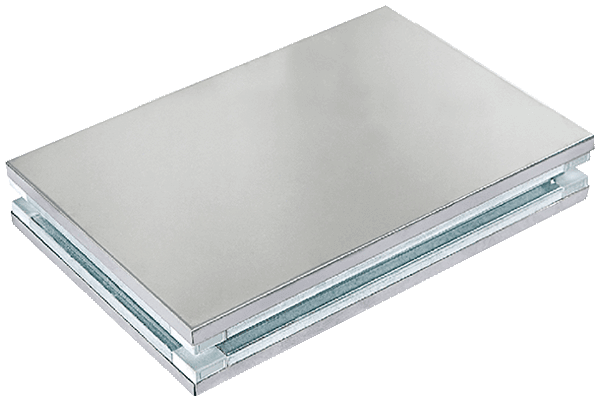

Jiangsu Rongshida Purification Technology Co., Ltd. is Handmade stainless steel sandwich panel-Cleanroom Wall Panel System Manufacturers, The company has carried out standardized management and insisted on refined production for the past two decades. Signed a quality inspection technical service agreement with the local technical supervision bureau, passed the GB/T19001:2016/ISO9001:2015 quality management system certification, and our wholesale Handmade stainless steel sandwich panel-Cleanroom Wall Panel System has been tested and certified by the National Fixed Fire Extinguishing System and the Quality Supervision and Inspection Center for Fire-resistant Components.

Now we have one manual panel hot pressing automatic assembly line, two manual panel traditional assembly lines, one machine-made panel production line, one purification steel door and one purification window production line. The daily production capacity of manual plates is 3000 square meters, the daily production capacity of machine-made plates is 3000 square meters, the monthly production capacity of purified steel doors is 3000 square meters, and the monthly production capacity of purified steel doors is 6000 square meters.

Contact Us >>