2024-02-26

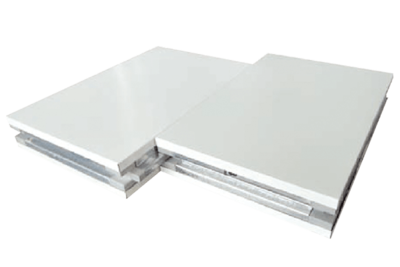

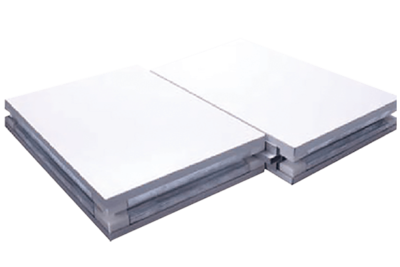

How does the anti-dropping mechanism of the Anti-dropping Manual Top Plate function?

The specific functionality of an anti-dropping mechanism in an Anti-dropping Manual Top Pl...

The specific functionality of an anti-dropping mechanism in an Anti-dropping Manual Top Pl...

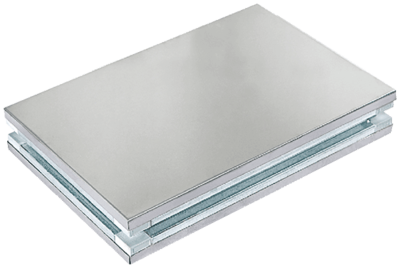

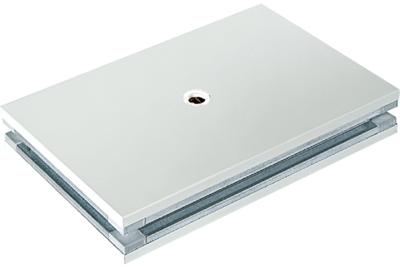

While rock wool sandwich panels are durable and require minimal maintenance compared to so...

The costs of using rock wool sandwich panels compared to other insulation or building mate...